SUCCESSES

🔹 Pallettizzazione con riconoscimento QR-Code

📦 Doppia linea produttiva – Smistamento automatizzato su base QR

📍 Un solo punto di pallettizzazione, massima efficienza logistica

🔁 Due linee di produzione, 8 macchine di incartonamento, un unico sistema centralizzato.

📷 Lettura automatica dei QR-Code per la tracciabilità e il corretto indirizzamento dei colli.

🚀 Affidabilità e riduzione degli errori in uscita.

🔷 Marcatura automatica ad alta precisione integrata in linea esistente

📌 Espansione produttiva tramite isola robotizzata

📍 Marcatura + Visione + Carico/Scarico

📄 Il sistema è stato progettato per integrarsi in una linea esistente e garantire una marcatura rapida e precisa. Il successo iniziale ha portato il cliente a richiedere il raddoppio della capacità con l’aggiunta di una seconda marcatura.

💡 Ogni pezzo viene posizionato con precisione tramite sincronizzazione software, garantendo performance elevate.

📊 Marcatura ogni 8 secondi – Tracciabilità in tempo reale – Espandibilità del sistema a moduli

🔷 Isola robotizzata per piantaggio boccole e marcatura

📌 Assemblaggio automatico con cambio formato rapido

📍 Piantaggio + Marcatura + Tracciabilità

📄 I pezzi vengono accumulati, piantati su pressa e marcati per la tracciabilità, il tutto in ciclo continuo. Cambio prodotto gestito in tempi record.

💡 Layout compatto con alta efficienza e adattabilità a lotti variabili.

📊 Cambio formato in 2–5 minuti – Isola integrata completa – Massima flessibilità operativa

🔷 Isola robotizzata per carico e scarico con filettatura automatica

📌 Manipolazione automatizzata di pezzi lunghi e pesanti

📍 Carico + Scarico + Filettatura + Oleatura

📄 I pezzi (fino a 2 metri e 20 kg) vengono gestiti da un robot a 7 assi che garantisce precisione, ergonomia e continuità operativa.

💡 Pulizia filetti e oleatura automatica integrate nel ciclo

📊 Riduzione sforzi per l’operatore – Magazzino integrato – Gestione completa ciclo vite

🔷 Sistema robotizzato per accumulo e orientamento di precisione

📌 Automazione dell'accumulo e ottimizzazione dei flussi

📍 Carico + Accumulo + Manipolazione

📄 Il sistema gestisce un'elevata quantità di pezzi, trattandoli singolarmente con precisione e corretto orientamento prima dell’operazione successiva.

💡 Ideale per linee ad alta produttività senza compromessi sulla qualità

📊 Riduzione tempi morti – Massima flessibilità operativa – Controllo robotizzato continuo

🔷 Movimentazione precisa di carichi pesanti e delicati

📌 Manipolazione robotizzata ad alta portata

📍 Forza + Precisione + Sicurezza

📄 Il sistema è progettato per sollevare carichi di grandi dimensioni mantenendo delicatezza e accuratezza, proteggendo anche i componenti più sensibili.

💡 Controllo costante della forza applicata – Manipolazione sicura dei materiali

📊 Robotica avanzata – Gestione carichi massivi – Trattamento delicato dei pezzi

🔹 Controllo 100% su calibro automatico

📌 Controllo dimensionale robotizzato

📍 Robotica + Metrologia

📝 Il robot gestisce il carico e lo scarico su calibro automatico da due linee in arrivo. Ogni pezzo viene tracciato lungo l’intero ciclo produttivo.

💡 Sistema integrato di controllo e tracciabilità su doppia linea.

📊 Precisione ±0,05 mm – Integrazione con calibro elettronico – Tracciatura dati automatizzata

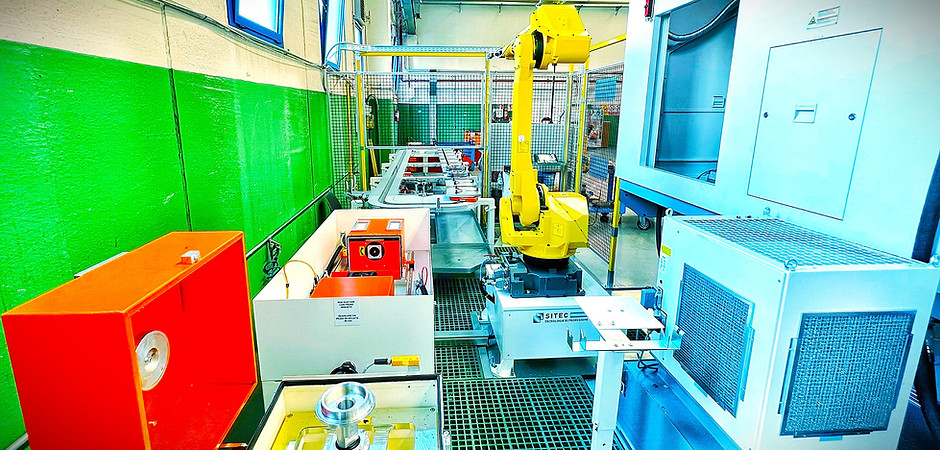

PRODUCTION OF CROWNS AND SHAFT ... WITH A SINGLE FLEXIBLE SYSTEM

A modular solution that allows our customer to manage the random production of crowns and shafts of various sizes from a single loading and unloading point.

The operator takes care of the loading of the crowns or raw shafts on the SITEC TP20 Conveyor Line, our SITEC Robotized Island precisely serves the Hobbing Machine, once the pieces have been processed, they are brought to Centrifuges of Our Production, then Marked and subsequently they are deposited on our pallets to return to the operator, processed, cleaned and traced.

A reliable, flexible and intelligent system. 100% Made in Italy by SITEC.

WHEEL GROUPS FOR VANS, TRUCKS AND CAMPER

A modular solution that allows our customer to manage the production of four machining centers from a single loading and unloading point.

The operator takes care of the loading of the blanks on the SITEC TP20 Transport Line, the four SITEC Robotized Islands precisely enslave their respective CDLs, once processed the pieces are redeposited on our Pallet and continue on our Intelligent Conveyor Belt for subsequent Marking, Washing and Control Operations, all in Automatic, until they return to the Loading and Unloading area ready to be assembled.

Totally installed by our Technical Team, Software engineers and testers.

A reliable, flexible and intelligent system. 100% Made in Italy.

This is SITEC.

ISO 14001 CERTIFICATION

Not a goal, but an important crossing point.

To further enhance the dedication and constancy with which we commit ourselves every day to leave the next generations a better future.

VERIFICATION OF PROCESSING

Quality check with cameras from presence of the processes, their positioning, their quality and their dimensions.

Accuracy of recognition +/- 0.05 mm without the need to stop our transport.

PALLET TRANSPORT OF UPRIGHTS

Machining of cast iron pillars for cars destined for the international market.

Four loading / unloading stations with the possibility of producing different families of pieces at the same time.

Our pallets memorize the type of piece that is loaded and allocate it to the correct machine for processing. They will then return to the same bay they started from.

PRODUCTION LINE FOR SPECIAL SUSPENSIONS

Double Machining Operation (OP10 + OP20), Marking, Blowing, Type Control, Traceability, loading and unloading in ergonomic positions.

The turnkey solution from raw to finished by SITEC guarantees speed, quality and efficiency.

PALLETIZATION BALL TAPS

When we are asked if we are able to unload a machine that produces spheres for taps at a cycle time of 2 "(two seconds) ... we simply create the ad hoc solution, bringing home what for us is the main objective. ... a satisfied customer.

The customer only has to turn on the machine and load the empty platforms for unloading, our automation at the end of the shift will return thousands of balls ordered and ready to be shipped.

WITHDRAWAL IN BULK

With infinite possibilities of flat or inclined positioning and in all its 360 ° of freedom, however it arrives we are able to take it from the belt and deposit it in the correct position depending on the type.

INTELLIGENT HANDLING OF ROTORS

An intelligent programming is that which allows a multitude of families to set a few parameters without having to take even a point on the Robot.

When it comes to pieces over a ton this becomes more fundamental than ever and the precision of the algorithms does not allow the slightest mistake.

This is why customers rely on us: for our reliability, for our precision and for the efficiency that the customer earns.

HIGH FLEXIBILITY LOADING / UNLOADING ISLAND OF PINIONS

Sometimes you load right and unload left or maybe reverse and load left and unload right, then on the other particular you unload on both bays, that piece you mark, the one you don't mark but you check it, the other still has to do processing one but not two, ... for our software engineers the greater the flexibility, the greater the satisfaction in realizing the solution.

MARKING OF NAVAL INJECTORS

From very small injectors with Datamatrix of 5 mm size up to larger pieces with laser markings even in rotation.

Thanks to the data entry and tracking system, the creation possibilities are endless.

STEERING GROUP PARTICULAR HANDLING

Two robots with a capacity of 125 kg each can load and unload a production line of uprights with cycle times of less than 18 ".

The recognition with a camera of every detail to verify its position and type, gives an even greater tone of safety and reliability to the system.

GEAR HANDLING AND MARKING

With an unloading at the end of the line, we mark the lot, date, type and any other data that the Customer requests from us depending on the production.

The piece is subsequently housed on special blister packs for the conservation of the pieces without them hitting each other once processed.

PALLET TRANSPORT OF CROWNS

Different types of parts with long to short life batches require highly flexible design and manufacturing.

Our Pallet conveyor lines are the perfect compromise for dynamic production where re-tooling is required in a very short time.

TOOTHED WHEELS HANDLING

From raw to finished in a single Machining Island with attached orientations of the pieces, vision for bulk picking, marking of production data.

With fast cycle times, with frequently changed production batches, we always know how to find the solution that gives the customer the highest efficiency available.